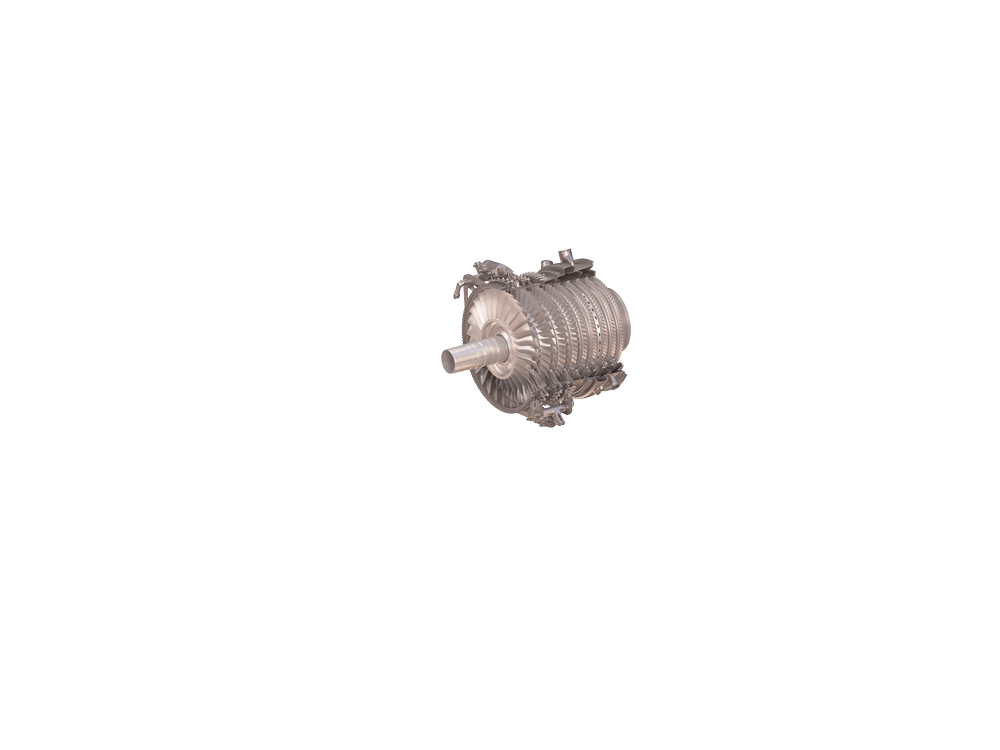

Take a Look Under the Hood of the GP7200

The confidence built into the GP7200 engine design comes from the historic collaboration of two industry giants, General Electric Co. (NYSE:GE) and Pratt & Whitney, a Raytheon Technologies business (NYSE:RTX). Based on engine technology that's been proven over 72 million hours of reliable operation from two companies with nearly two centuries of combined experience. The advantage shows in every part.

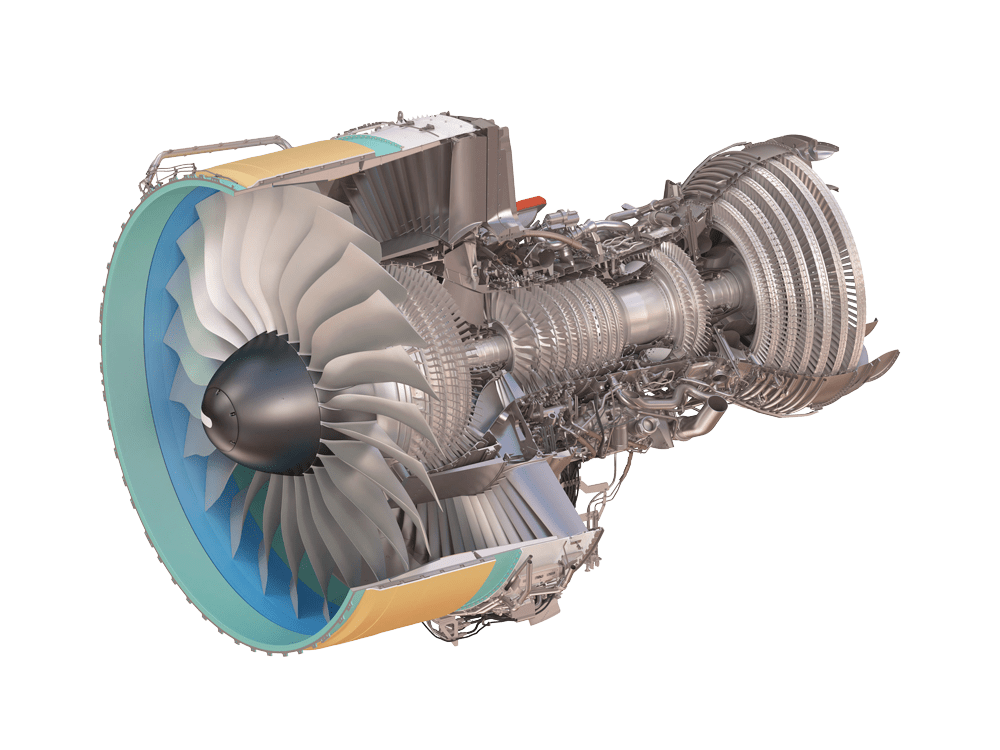

Full Engine

Heritage

GE90 and PW4000

Thrust

70,000 to 81,500 lb

(311 to 363 kN)

Fan diameter

116 in

(296 cm)

Bypass ratio

8.8

Pressure ratio

36+

Architecture

1-5-9-2-6

Noise

Stage 4 – 17 dB

Emissions

CAEP/8

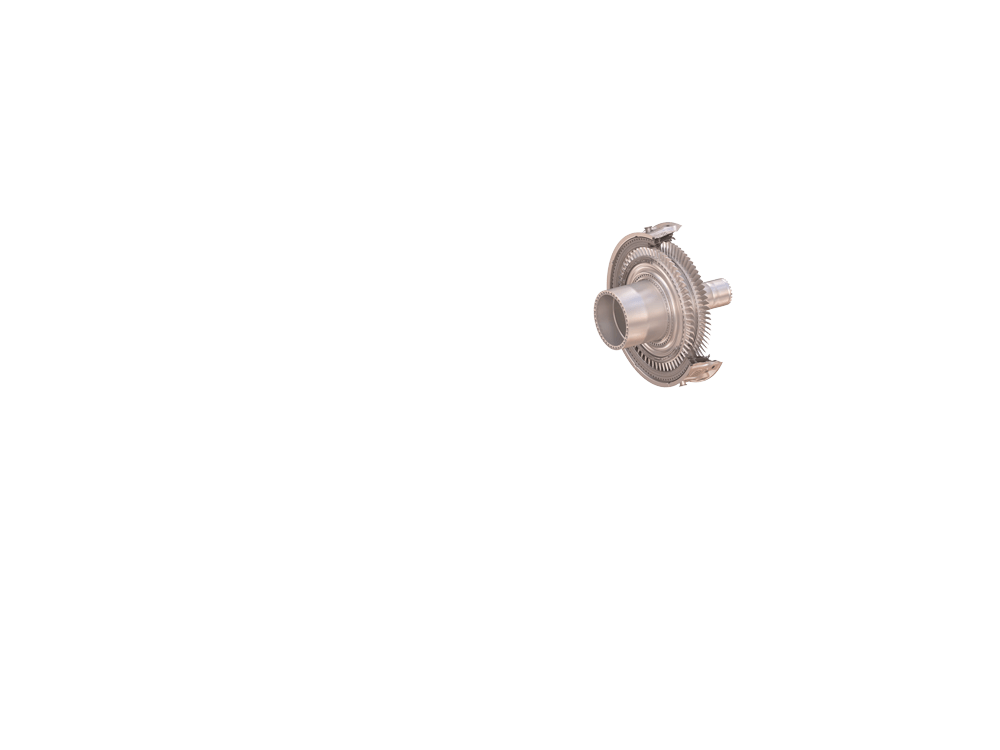

Fan Module

Built by Pratt & Whitney

24 swept fan blades

116" wide chord hollow titanium

Quietest A380 engine

Low-noise acoustic architecture

Durable

FOD and erosion resistant

Maintainable

Single blade repair or on-wing replacement

LOW PRESSURE COMPRESSOR (LPC/BOOSTER)

Built by SAFRAN aero boosters

5-stage design based on PW4000

High efficiency

3D aero improves fuel burn and EGT margin

Durable

Low particle ingestion with high dirt rejection

HIGH PRESSURE COMPRESSOR (HPC)

Built by SAFRAN aircraft engines

9-stage design based on GE90

Low-noise acoustic architecture

High efficiency

3D aero with first stage blisk

High performance retention

Thermally matched casing and rotors

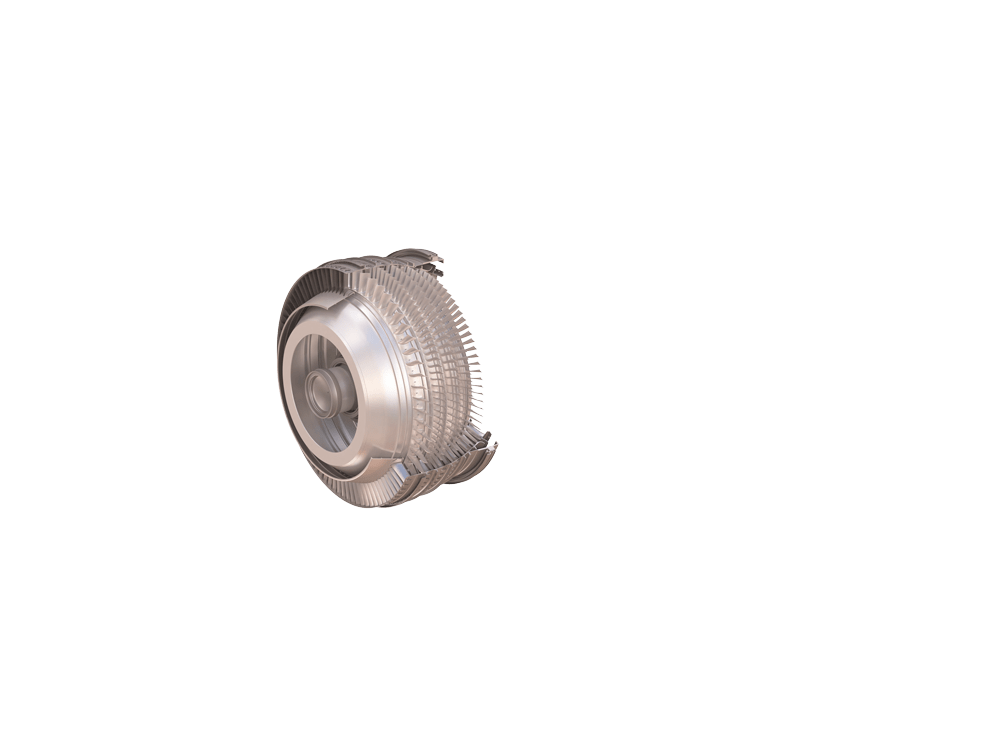

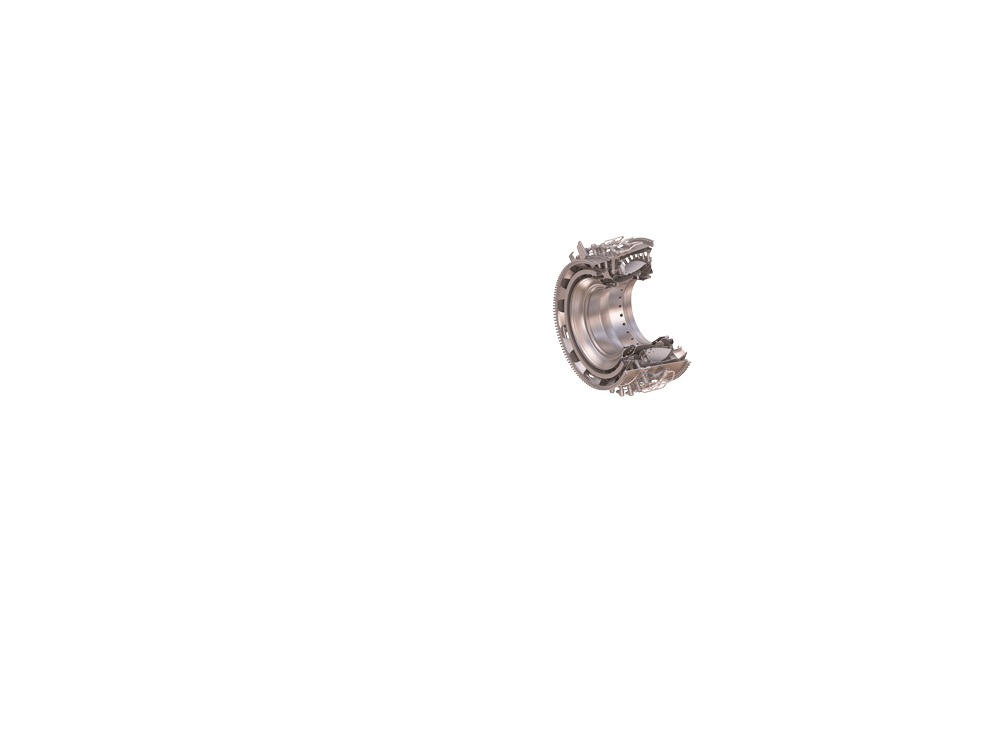

SINGLE ANNULAR COMBUSTOR (SAC)

Built by GE Aviation

Derived from GE and CFM technologies

CAEP/8 compliant emissions

Short SAC for low maintenance

HIGH PRESSURE TURBINE (HPT)

Built by GE Aviation

2-stage design based on GE90

High performance and durability

3D aero with split blade cooling

Low maintenance cost

Boltless rotor for fewer parts and longer life

LOW PRESSURE TURBINE (LPT)

Built by MTU Aero Engines

6-stage design based on PW4000

High performance

3D aero with hollow airfoils

Low noise

Acoustic cut-off design

FULL AUTHORITY DIGITAL ENGINE CONTROL (FADEC)

Built by GE Aviation

Based on GE90 and CFM technologies

Advanced motoring

Performance trending and remote diagnostics

Advanced processing

Redundant sensors to reduce delays and cancellations